Our Products

Because we stock one of the most extensive inventories of sealing products in the world, Rocket Seals has served every industry (OEM and MRO) imaginable.

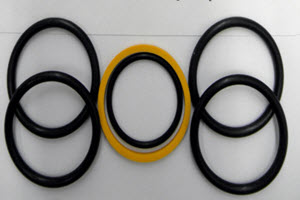

We stock O-Rings, Quad Rings, Hydraulic Seals, Mechanical Seals, Oil Seals, Piston Seals, and much, much more, so we can be your one stop shop for all your sealing needs.

Trust Rocket Hose & Fittings for your OEM and MRO (made-to-order and while-you-wait) hydraulic and industrial hoses and accessories.

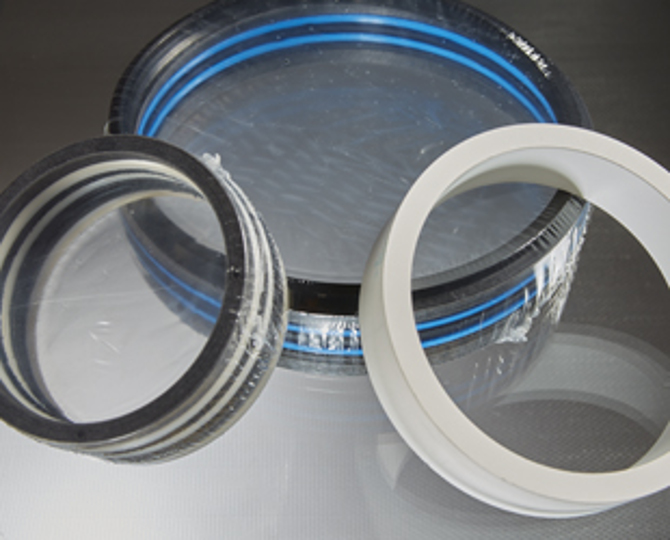

Custom Seal Kits

Our custom kits for OEM customers ensure efficient manufacturing processes and for MRO customers to optimize their equipment uptime. We’ll help you make sure you have the right parts, at the right time, and at the right place.

Industries We Serve

Our clients include everything from aerospace to oil and gas, medical equipment to food and beverage and more. We serve customers from the largest global manufacturers to INC 500 companies.

What Our Partners Say

Experience and Expertise Since 1956

For over 60 years, Rocket Seals has been serving OEM as well as MRO customers around the corner and around the world.

Rocket Seals fields an industry leading, long-tenured, highly trained and experienced sales and customer service team.

Rocket Seals Resources

Get all your important questions answered and learn more about our sealing products, materials, industries we serve, and more.